Flying Bowling Ball-up Machine

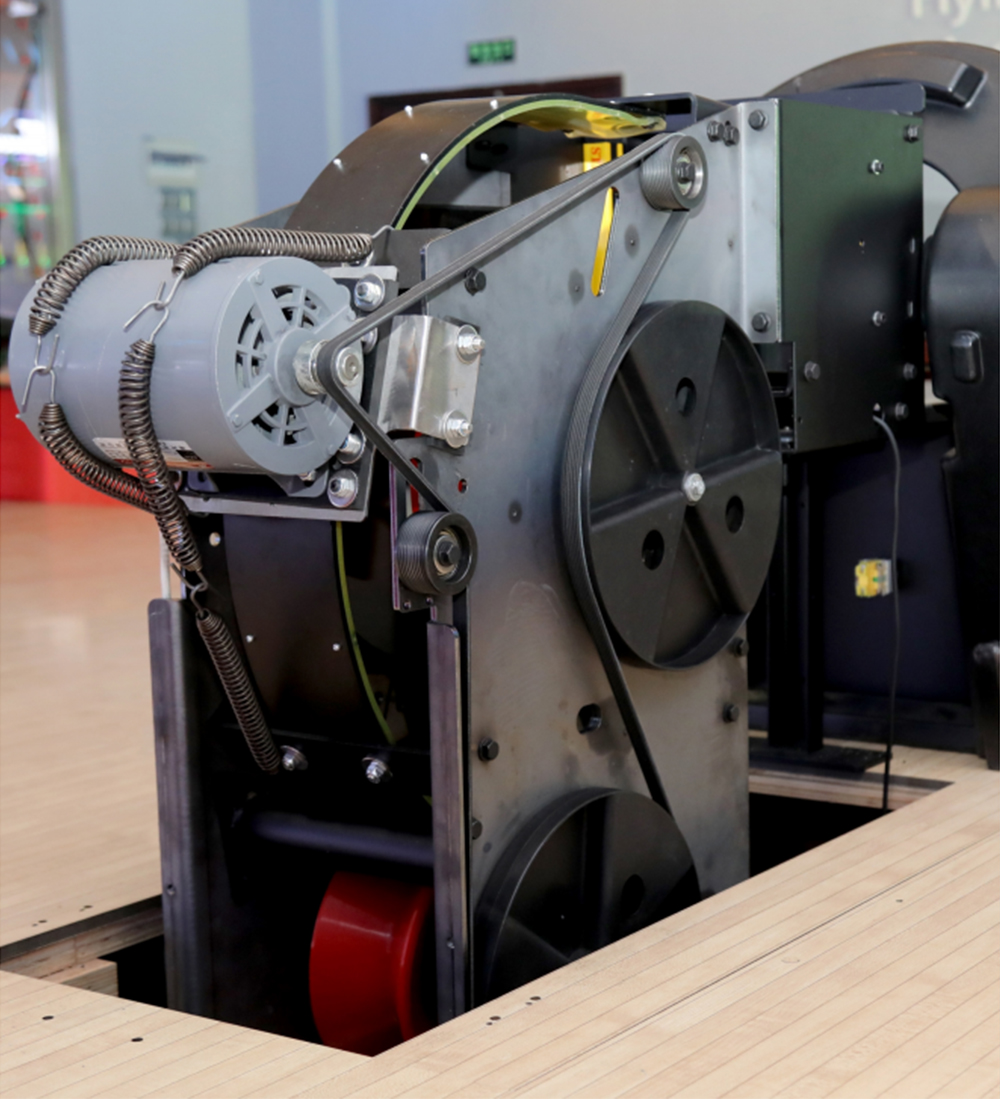

Known for its exceptional work in the field of bowling equipment, Flying is dedicated to continuously innovating and perfecting its bowling ball-return system. As an essential component of the system, our ball-up machine has undergone several iterations.

Known for its exceptional work in the field of bowling equipment, Flying is dedicated to continuously innovating and perfecting its bowling ball-return system. As an essential component of the system, our ball-up machine has undergone several iterations. From initial independent research and development to large-scale production, then to meticulous problem discovery and solution, Flying always adheres to the attitude of striving for excellence and continues to optimize and upgrade the ball-up machine.

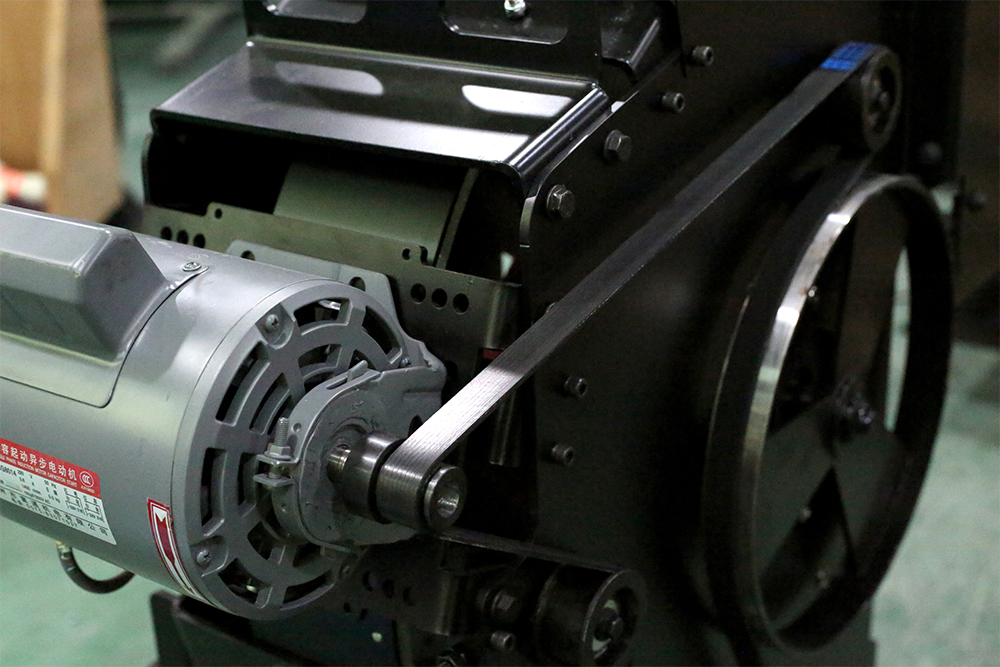

During independent research and development, Flying engineers have put their professional knowledge and skills to full use. Our engineers thoroughly studied the market demand, carefully analyzed the user feedback, and well designed the new ball-up machine that integrates cutting-edge mechanical technology and electronic control technology to make the ball moving process faster and more accurate.

The successful design and production of the second-generation ball-up machine have not only improved Flying’s market competitiveness but also brought the customers a better experience. It fully demonstrates the technical strength and innovative spirit of Flying Engineers and lays a solid foundation for the company's development in the field of bowling equipment.

However, after mass production, the engineers found in practical use that the ball-up machine would occasionally get stuck and generate excessive noise. Realizing that the problems must be solved, the engineers immediately contributed to investigating. After trials and improvements, the engineers finally found the problem sources and successfully proposed a solution. They not only optimized the mechanical structure of the ball-up machine but also upgraded its motor control system, which made it work stably in all kinds of environments. Moreover, the ball-up machine noise during working is remarkably reduced by advanced noise reduction technology.

Flying’s engineers didn’t stop there. During mass production and practical use of the second-generation ball-up machine, they found another problem that caused the ball to slip during rotary rise, reducing the efficiency of the ball moving process. To solve this problem, our engineers redesigned and modified the ball-up machine’s structure and carried out a mould opening. This improved the machine’s efficiency and further enhanced its stability and reliability. However, this is just the beginning. The real challenge is how to transform a design into a real and reliable product.

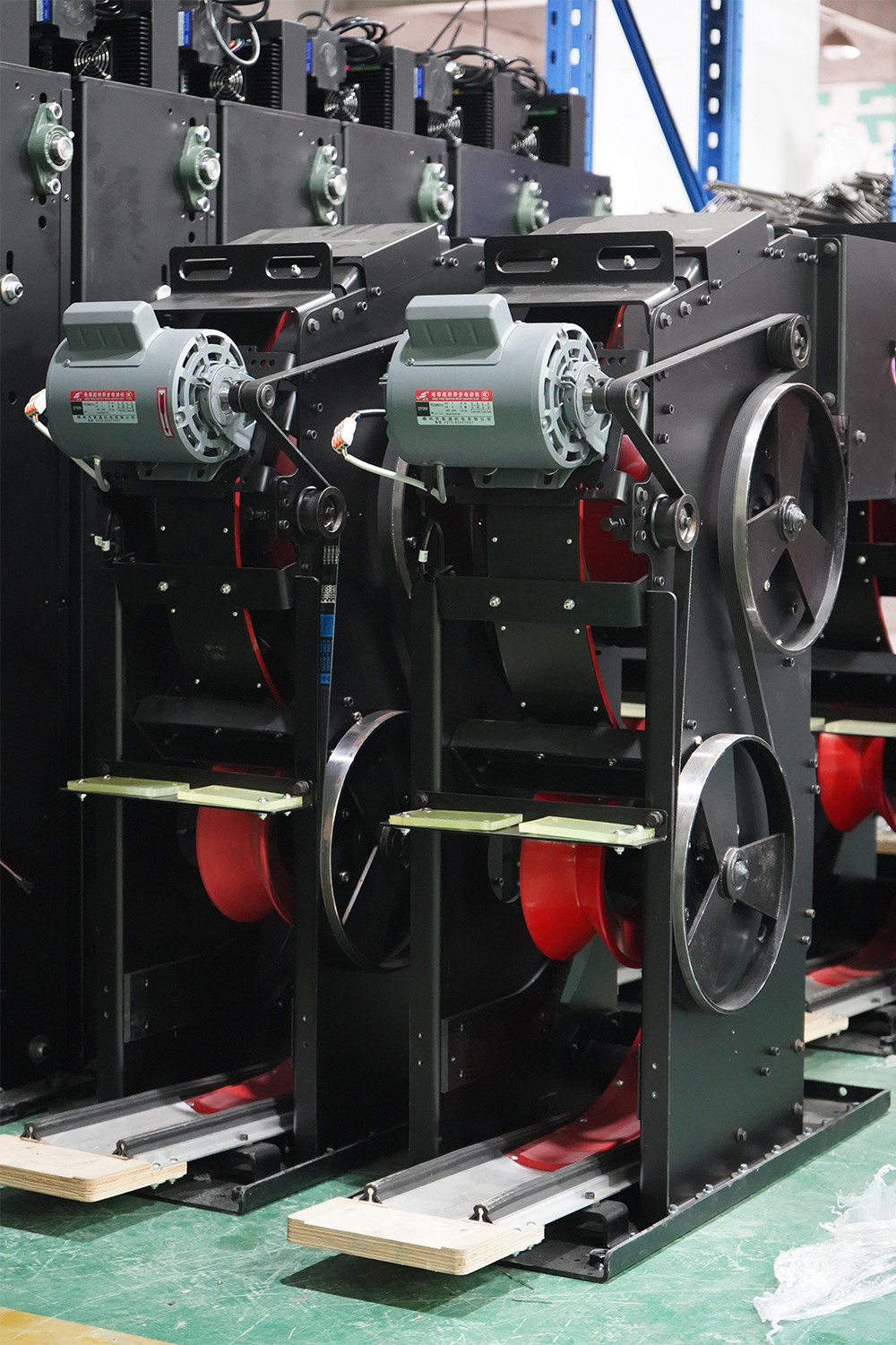

Flying values precision. Every ball-up machine has to undergo a rigorous inspection. Flying is not only producing a machine, but also offering a safe and fun experience for the bowlers. Therefore, from the beginning of product design to the finished product, every step works with rigorousness and meticulousness.

During material selection, the engineers rigorously choose and test each material to ensure that it can withstand any extreme condition the machine may encounter when it is working. These materials are then carefully processed and molded into the various parts of the ball-up machine.

When all parts are ready, assembly begins. It’s a process that requires great precision and patience, in which every screw and interface needs to be carefully inspected and adjusted.

However, the completed assembly isn’t the end of the work. Instead, it’s the start of the entire inspection. After the assembly, each ball-up machine will be tested tens of thousands of times to simulate all situations that the machine may encounter in actual use for anomaly detection. From sound to temperature to vibration, the engineers paid close attention to every detail of the machine during the testing, and no anomaly could escape their eyes. Once a problem is found, they immediately stop testing and conduct an in-depth investigation and repair.

Such rigorous testing ensures that every ball-up machine meets the highest quality standards. It also ensures that the bowlers are provided with a safe and reliable product. When the bowlers are playing in the bowling alley, they can feel the machine’s smoothness and stability, from which the engineers’ hard work and rigorous attitude take credit.

With the continuous progress of science and technology, the ball-up machine may be further upgraded in the future. But in whatever case, Flying engineers’ pursuit of quality and strong sense of responsibility will never change. For them, this is not only a job, but also a mission and responsibility.

Flying is always committed to providing customers with products and services of the highest quality. Through continuous innovation and improvement, Flying will continue to lead the development of bowling equipment.

What is the Size of a Bowling Lane? | Flying

How Much Does a Bowling Lane Installation Cost? | Flying

Bowling Alley Costs: Your Guide - Flying

Is Bowling Profitable? - Flying

Bowling Equipment Cost: A Complete Guide to Building Your Dream Bowling Alley

Bowling Equipment

How much to put a bowling lane in your house?

Building a bowling alley in your house may seem very expensive. But at Flying, you can get top-quality bowling equipment from us at very affordable prices. You can have the fun of bowling at home without requiring a lot of money or effort.

Product

How many lanes does it take to open a bowling alley?

There's no strict rule on the number of lanes required to open a bowling alley. It depends on your business goals and target market.

Here's a breakdown to help you decide:

- Small niche alleys: Some bowling alleys might focus on a specific audience, like a boutique bowling alley with just a few lanes catering to a high-end clientele. They might have other revenue streams besides just bowling, like a fancy restaurant or bar.

- Traditional bowling alleys: These typically have many lanes, often around 8 to 24 lanes , to accommodate a larger number of bowlers and maximize revenue through lane rentals.

- Mini bowling: Certain alleys might offer mini bowling, which uses lighter balls and shorter lanes. This could be a good option for a family entertainment center and wouldn't require a large number of standard lanes.

Ultimately, the number of lanes is a business decision based on your target market, budget, and the overall experience you want to create.

How a bowling ball return machine works?

A bowling ball return system uses a combination of gravity, belts, and sometimes lifts to bring your ball back to you after your roll. Here's a breakdown of the typical process:

-

Ball Exit: After rolling down the lane, the ball exits into a channel at the end. This channel might have a slight incline to help guide the ball towards the return mechanism.

-

Transfer Tray: The ball rolls into a shallow tray or trough. This tray might have a diverter at the end to ensure balls from adjacent lanes don't collide.

-

Elevator or Incline (optional): In some setups, the ball might be lifted to a higher level before entering the return system. This creates a steeper decline for the ball to travel down, helping it gain momentum.

-

Belt Conveyor: The ball reaches a conveyor belt with a textured surface to prevent slipping. This belt carries the ball up an incline.

-

Gravity Channel: Once at the top of the incline, the ball is released onto a long, U-shaped channel. Gravity takes over, pulling the ball down through the channel.

-

Ball Deflector: At the end of the channel, there might be a deflector that diverts the ball slightly towards your lane. This ensures the ball ends up in the correct return slot.

-

Ball Return Tray: The ball finally reaches a tray or cradle positioned in front of your lane, ready for your next roll.

Here are some additional points to note:

- Modern systems might have sensors to detect the presence of a ball and activate the return mechanism accordingly.

- Some higher-end systems use quieter materials and designs to minimize noise during ball return.

Price

how much does a bowling lane cost ?

The cost of a single bowling lane falls between $75,000 and $80,000 for a standard lane. Here's a breakdown considering different factors:

New vs. Used:

New lanes naturally cost more than used ones.

Features:

Automatic scoring systems or other customizations can increase the price.

Home vs. Commercial:

Lane installations for homes may cost slightly more to account for special adjustments.

It's important to note that this is just the lane itself. The total cost of building an entire bowling alley will include additional costs for installation, surrounding infrastructure, and any amenities you include.

Flying Ultra Standard Bowling String Pinsetter

Flying Ultra Standard Bowling(FUSB) Upgraded Version: The string pinsetter is based on the latest technology. A more pleasant bowling experience benefits from innovative designs that incorporate today's latest technology.

Flying Smart Duckpin Bowling

Flying Smart Duckpin Bowling (FSDB) innovative design, standard 9.2-meter short lane, can be shortened in length, compact layout suitable for small spaces. The game rules are simple but challenging, attracting players of different ages to actively participate.

Suitable for social entertainment venues such as bars, billiard halls, and game centers, it not only enhances interactivity, but also increases the popularity and consumption frequency of the venue. The fun and competitive nature of FSDB will make it a new focus of social activities.

Brand New String Pinsetter Mini Bowling Equipment Small Ball And Pin

Flying Cute Mini Bowling (FCMB) is a mini bowling experience designed for children and families. The lane length is fixed at 12 meters, equipped with lightweight balls without finger holes (only 1.25kg) and small pins, specially designed for children and family fun.

It can not only help children feel the fun of bowling, but also stimulate their interest and competitive consciousness. Suitable for children's playgrounds, theme parks and parent-child centers, it is the best choice for places focusing on the children's market.

Indoor Medium Duckpin Bowling Lane Equipment For Bowling Alley

Flying Social Medium Bowling (FSMB) is tailored for small venues, with flexible lane lengths (customizable from 9.6 meters to 18 meters), a small ball design suitable for players of all ages, and light pins that are easier to knock down, increasing participation and fun.

Whether it is a gathering of friends or a casual social, FSMB can easily create a relaxed and pleasant atmosphere. Its efficient space-utilization design is particularly suitable for cafes, bars and community entertainment venues, allowing people to fall in love with bowling in a relaxed interaction.

Contact Flying

Start your custom bowling alley project

If you contact us now for more details, we can provide you with a custom bowling alley service. Our service team will get back to you within 24 hours normally!

© 2024 Flying BOWLING. Designed by gooeyun